|

Machine Design Services

A typical machine developed by Machine Design Services contains

upwards of 60 cams and operates at 100 parts per minute. Before

cutting a single piece of metal they test for clearances, timing,

bearing loads, and part accelerations using Dynamic Designer.

|

|

|

Kimberly-Clark Corporation

Paper products manufacturer Kimberly-Clark used Dynamic

Designer/Motion software from Mechanical Dynamics to study the

design of its unique Kleenex(R) tissue-packaging equipment in

operation. As shown here, cardboard cartons are moving through the

machine and opened so tissues can be inserted. Animation shows the

interaction of the cartons and transfer lugs. The cartons are

displayed transparently to show the action of the background

parts.

|

|

|

Machine Manufacturers Australia

At Machine Manufacturers Australia (MMA), engineers apply

Dynamic Designer/Motion to check for interferences between parts and

test for forces, stresses, and deformation. This helps assure that

parts are correctly sized, material waste is minimized, and

strength requirements are safely met.

|

|

|

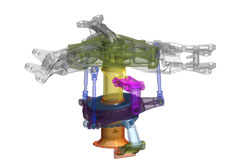

Moscow Helicopter

Dynamic Designer/Motion, enables engineers to quickly and

interactively modify their designs and perform motion simulations

within the standard drawing file.

|

|

|

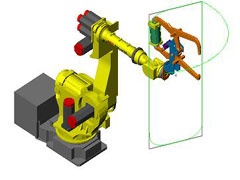

Fanuc Robotics

Dynamic Designer allowed Fanuc Robotics to validate the actual

dynamic path of the Fanuc S-430iw robot while carrying the

customer’s desired payload without any physical testing.

|

|

|

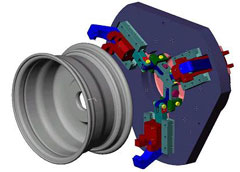

Ward Machine Tool

Ward Machine Tool's challenge is to design a

dual-actuated/multi-range aluminum wheel lathe chuck. Virtual

tests revealed actuator sizing and ping shearing requiring

significant design rework. The problems were identified without

any physical testing.

|

|

|

Cook

Engineering

Using Dynamic Designer/Motion, Cook Engineering Services

performed a complete dynamic analysis of a motion base simulator

currently in use at a San Francisco entertainment center. Cook’s

analysis quickly informed the client about electric motor torques,

bearing loads, and vibration of the image projection equipment.

|

|

|

Unlimited,

Inc.

Unlimited’s challenge with the Lynch glass-pressing machine

design was to determine torque caused by a damping cyclinder

failure under normal operating and crash conditions. By simulating

the crash test with Dynamic Designer Motion, Unlimited was able to

determine optimum normal-operation and worst-case mounting pad

loading factors.

|

|