SimWise 4D

Motion Simulation, Stress Analysis, and Optimization

Optimization

Once you know a design will work and is strong enough to operate safely, you can start to consider making trade-off between product attributes in the areas of weight, cost, manufacturability, and performance. SimWise 4D contains the HEEDS© optimization engine from Siemens Digital Industries Software whichs rapidly iterates through many design alternatives looking for design parameters that meet all targets and criterias.

Three things are needed for optimization:

- Parameters - The values that will be changed to achieve an optimized objective. These can be any type of SimWise value, such as the stiffness of a spring, or the location of a joint.

- Objective - The value(s) to be optimized. Any SimWise quantity that can be displayed on a meter can be an objective.

- Constraints - Place bounds on the optimization. Any SimWise quantity that can be displayed on a meter can be used as a bound.

As the optimizaiton runs, the engine will choose different values for the parameters and run multiple Motion, FEA, or Motion+FEA simulations. The high performance search algorithms in the HEEDS© engine guide the choice of parameter values. The data from each run are preserved and can be reviewed. Each run is ranked in terms of how it meets the optimization criteria and the rankings can be used to arrive at the final values used for your design.

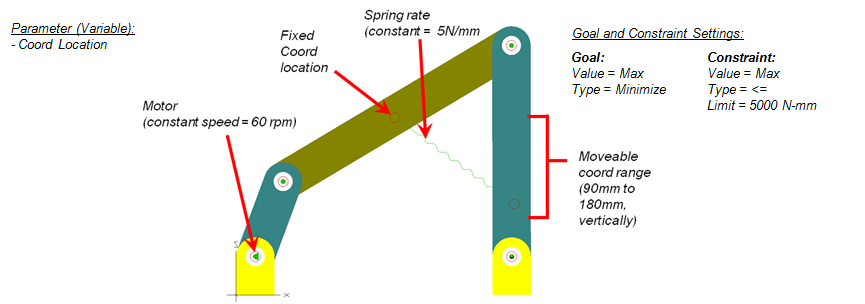

An example is show in the simple model:

The goal is to determine the location of the spring end attachment such that the maximum torque on the motor is less than or equal to 5000 N-mm

The variable is the Y coordinate of the spring attachment point.

The objective is to minimize the maximum value of the motor torque.

The constraint is that the maximum value of the torque is less than or equal to 5,000 N-mm

Quote

Quote Evaluation

Evaluation